Hydraulic Quick Coupling: Technical Specifications & Standards Guide

In today’s high-demand industrial environment, the reliability of hydraulic systems depends significantly on the quality of their components. Among these essential components, hydraulic quick couplings stand out as critical connection points that can either enhance or compromise your entire system’s performance. At Hessan, we’ve spent decades perfecting our hydraulic quick coupling technology to meet and exceed global industry standards.

Understanding Hydraulic Quick Coupling Specifications

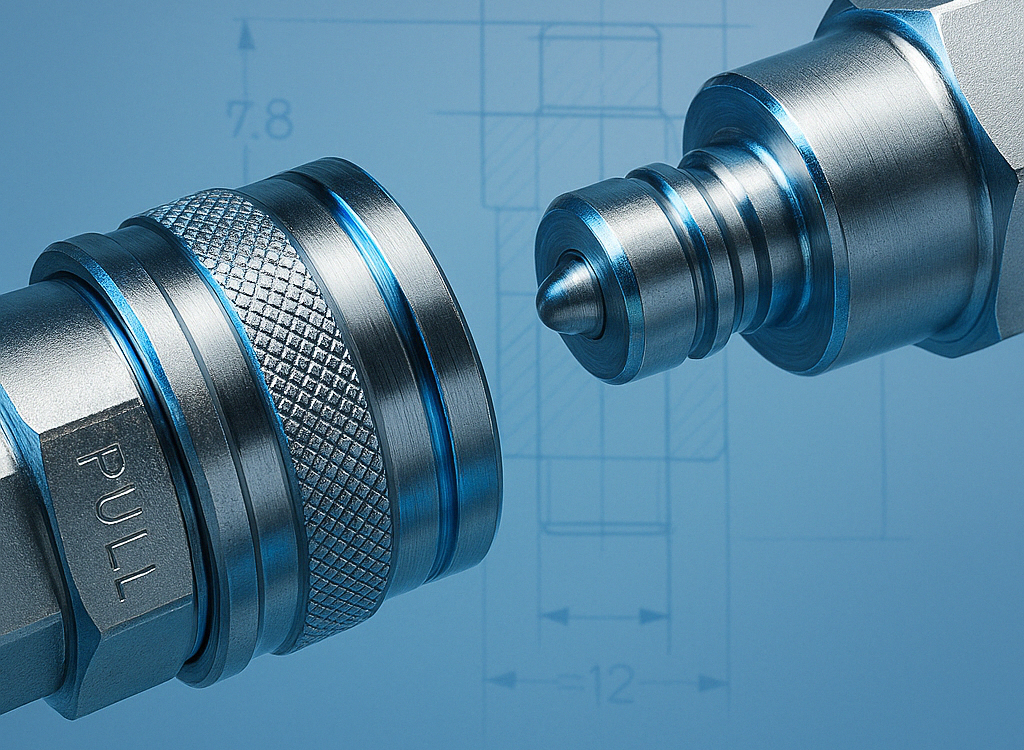

Hydraulic quick couplings (also known as quick connects or quick disconnects) serve as the vital link between hydraulic lines and equipment. These specialized fittings allow operators to connect or disconnect hydraulic lines swiftly and safely, even under challenging conditions. However, not all hydraulic couplings are created equal, and understanding their technical specifications is crucial for optimal system performance.

Pressure Ratings: The Foundation of Reliability

The working pressure capacity of hydraulic quick couplings directly impacts their application suitability. Our premium hydraulic quick couplings feature:

- High-pressure ratings up to 6,000 PSI (413 bar) for heavy-duty industrial applications

- Medium-pressure options ranging from 3,000-4,500 PSI (207-310 bar) for standard equipment

- Low-pressure variations starting at 1,500 PSI (103 bar) for specialized applications

Each coupling undergoes rigorous burst pressure testing, typically achieving safety factors 4x greater than their rated working pressure, providing you with unmatched reliability and peace of mind.

Flow Capacity: Ensuring System Efficiency

Hydraulic quick connect flow capacity determines how efficiently fluid power transfers through your system. Our engineered couplings feature:

- Maximum flow rates up to 120 GPM (454 LPM) for high-volume applications

- Optimized internal geometries minimizing pressure drops across connections

- Specialized flow path designs reducing turbulence and system inefficiency

By selecting the appropriate flow capacity for your application, you can avoid power losses, excessive heat generation, and premature component failure in your hydraulic systems.

International Standards Compliance

In the global marketplace, adherence to recognized standards ensures compatibility and safety across hydraulic systems. Our hydraulic quick couplings meet or exceed:

ISO Hydraulic Coupling Standards

Our product line complies with critical ISO standards including:

- ISO 7241 (Series A and B) governing interchangeability and performance requirements

- ISO 16028 for flat-face coupling designs with enhanced environmental protection

- ISO 18869 for contamination control during connection/disconnection cycles

These standards ensure our hydraulic quick connects integrate seamlessly with your existing equipment while maintaining optimal performance.

Thread Size Compatibility

Proper thread compatibility prevents leakage and ensures secure connections. Our comprehensive coupling line features:

- NPT (National Pipe Thread) standards for North American applications

- BSPP (British Standard Parallel Pipe) for European and global markets

- Metric thread specifications for international equipment compatibility

- JIC (Joint Industry Council) standards for high-pressure applications

Each thread type undergoes precision machining and quality control to guarantee leak-free performance throughout your hydraulic system’s operational life.

Advanced Technical Features

Temperature Rating Excellence

Modern hydraulic systems often operate in extreme environments. Our hydraulic quick couplings maintain integrity across:

- Extended low-temperature ranges down to -40°F (-40°C) without brittleness or seal failure

- High-temperature performance up to 250°F (121°C) maintaining seal integrity

- Thermal shock resistance for applications with rapid temperature fluctuations

These temperature ratings exceed standard industry offerings, providing exceptional reliability for demanding applications in construction, agriculture, and heavy industry sectors.

Contamination-Resistant Design Elements

System contamination represents one of the primary causes of hydraulic failure. Our advanced coupling designs incorporate:

- Double-sealed valve mechanisms preventing environmental contaminant ingress

- Flush-face designs minimizing fluid spillage during connection/disconnection

- Protective dust caps safeguarding coupling internals during storage

These contamination control features extend system life and reduce maintenance costs by maintaining hydraulic fluid cleanliness.

The Hessan Difference

While many manufacturers provide basic hydraulic quick couplings, our engineering team has developed proprietary enhancements that deliver superior performance:

- Enhanced coupling materials offering 30% greater corrosion resistance than industry standards

- Precision-machined components with tolerances 50% tighter than required specifications

- Advanced seal technology reducing leak potential by 75% compared to conventional designs

- Connect-under-pressure capabilities up to 1,000 PSI (69 bar) for operational flexibility

These innovations result in hydraulic quick connects with extended service life, reduced downtime, and exceptional reliability in even the most demanding applications.

Selecting the Right Hydraulic Quick Coupling

Choosing the optimal hydraulic quick coupling involves careful consideration of your system’s specific requirements. Our technical team provides comprehensive consultation addressing:

- Complete system pressure analysis

- Flow requirement calculations

- Environmental condition assessment

- Connection/disconnection frequency evaluations

- Material compatibility verification

This consultative approach ensures you receive the perfect hydraulic coupling solution for your unique application needs.

Elevating Hydraulic System Performance

In today’s competitive industrial landscape, system reliability and efficiency provide critical competitive advantages. By selecting Hessan premium hydraulic quick couplings, you gain access to industry-leading specifications, global standards compliance, and innovative design features that maximize your hydraulic system’s performance.

Contact our technical team today to discuss your specific hydraulic quick coupling requirements and discover how our advanced connection solutions can enhance your operations.